From growing things to making things

There are opportunities to produce many goods without biology.

Biology makes the impossible possible, at a cost

There’s been a lot of excitement around the future of bio-manufacturing. I’m excited about it too, as I noted in a previous post:

It’s hard to overstate how broad these capabilities are. Yeast biochemistry can support a wide range of reactions, and in theory, virtually any organic molecule, protein, or biopolymer could be made by augmenting yeast with new genes. With sufficient scale, precision fermentation could produce medicines, replace our food system, and supplant much of the chemical industry using the same fermentation tank.

I still endorse the ideas in that post as methods to improve precision fermentation, but I’ve become less excited about using biology to manufacture simple products at scale. In another post, I pointed out that even producing food protein (which is relatively cheap) is extremely energy inefficient; chemical synthesis can do it 5 orders of magnitude better.

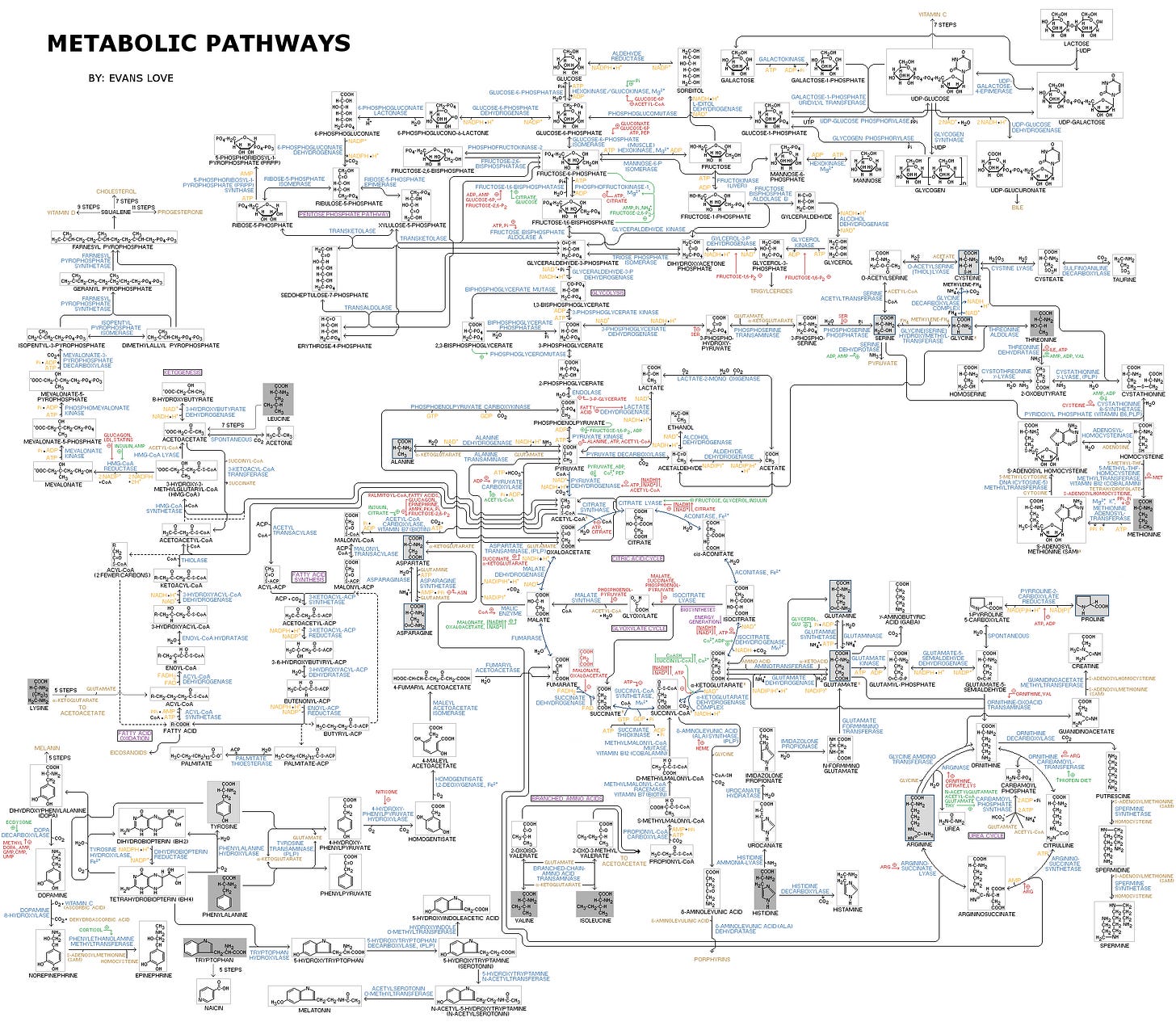

In the age of cheap energy, low efficiency isn’t a deal-breaker, but it is a symptom of a larger problem: biology is too complicated. Evolution has produced incredible ways to manipulate matter, but it’s a “blind watchmaker” that produces complicated solutions to problems. Worse, it’s difficult to build an understanding of biochemical networks and engineer them for our purposes.

Because biology is so complicated, adapting living systems to produce a new product is challenging. Life can be sensitive to small environmental changes and figuring out why something doesn’t work isn’t always feasible. For any product you might make, you’ll usually have to separate it from a complex broth used to support the microbe you’re growing. That’s why I focused on improving separations in my post on fermentation.

These issues compound to make the feedback loop in biology quite slow. It’s tricky to get a new idea working, slow to isolate the product, and hard to draw lessons from your failures.

Unless something changes, biomanufacturing will be stuck making bespoke, high-value products1.

Make biological processes non-biological

Many processes improve by taking biological components out of them.

We used wood to power furnaces, but trees grew too slowly to supply an industrial civilization. Switching to a massive stock of coal sparked the industrial revolution. Fossil fuels themselves are too limited for modern society, so we’re starting to switch to nearly-limitless sources like solar. Our energy systems have learned to rely less and less on biology because life just can’t keep pace with our growth.

Instead, we’ve learned to make things directly using mining and synthetic chemistry. Many chemically manufactured products have supplanted products that were originally manufactured biologically:

Plastics and synthetic rubber have replaced wood, natural rubber, leather, and other animal products.

Synthetic fibers like polyester and spandex have displaced (but not replaced) silk, cotton, and down in clothing. Other synthetic fibers used in rope have largely replaced plant-based fibers for this purpose.

Concrete and steel have replaced wood2 for most large structures.

Fertilizers once made from bat guano and other animal products are now produced synthetically from fossil fuels and air.

Iodine once made from kelp is now produced via mining.

Pharmaceuticals once sourced from plants like aspirin are now made chemically.

It’s hard to imagine biomanufacturing taking back the products that were supplanted by chemical products decades ago.

To be fair, biomanufacturing folks are usually focused on making complex products. There are things we still can’t make with synthetic methods like wood, cotton, wool, meat, proteins, nucleic acid sequences, and large molecules. As Ian McKay illustrates, biology is great for making complex products, while traditional chemistry is great for making simple products efficiently. Though biology has to run at room temperature and atmospheric pressure, it can leverage the mild conditions to place atoms with extreme precision. On the other hand, traditional chemistry can take advantage of high pressure and temperature to make things at a lower cost.

It’s nice that biology enables us to make things that we can’t build with existing chemistry, but in the long term we should be trying to remove living things from manufacturing processes to increase efficiency.

Building without biology

Can we build complicated stuff without having to tame the complexity of living things? I think so.

Pharmaceuticals are the primary reason we need to make complex organic molecules in the first place. Medicinal chemistry has a long history of using organic synthesis to make substances that tweak our biology. It’s kind of a grind though, it takes a huge amount of effort to figure out how to make even one molecule.

I’m optimistic that new tools might improve our ability to make small molecules. For one, groups like the American Chemical Society have been working to gather up all of the published data and create tools to help chemists plan a synthesis.

There has also been a push for more automation in synthetic chemistry with companies like Chemify, and groups like the University of Toronto’s Acceleration Consortium. Automation will lead to better standards in synthetic chemistry, paving the way for Frictionless Reproducibility.

Spiroligomers are an alternative approach to small molecule development, instead of trying to make every organic molecule, we can stick together building blocks that have a wide range of functionalities.

Despite these opportunities, organic synthesis probably can’t be used to make biologics. These are long polymers such as proteins that living things are particularly good at making. For these, we’ll need specialized approaches such as Modular peptides. My hope is that we can get most of the functionality of proteins by assembling small peptide modules that are within reach of synthetic methods.

Ultimately, I hope that these methods can replace most animal products. In addition to the moral case against them, animals use a lot of land and other resources. One founder of a cultivated meat company described meat production as medieval technology that’s prime for disruption3. Is there a path to making food products synthetically?

Consider milk, it’s a mixture of known proteins and fats and if we can make enough of these to reproduce milk’s properties, the entire dairy industry can shift away from using cows4. Eggs on the other hand would be more challenging, but we generally know what bundle of proteins and fats go in to making one, the challenge is doing so cheaper than chickens. Longer term, my hope is that modular peptides can one day reproduce the complex proteins found in meat.

Plants will be one of the last things to go, but we can chip away at their domain in a lot of ways:

Simple products like oils can be made synthetically, eliminating the need for oilcrops and butter.

There is work being done to produce starches and other carbohydrates. This would reduce the demand for potatoes, sugar, corn syrup, and flour.

We can produce wood-like substances synthetically which would save a huge amount of timberland.

Like with meat, modular peptides might displace soy products.

New polymers could potentially replace fibers like cotton and wool.

That being said, many plants are valued for their structure, taste, and nutrition. Any synthetic method to create something similar would require self-organizing machines similar to cells. At that point, you might as well grow them directly5.

Conclusion

Biology, for all of its incredible abilities, is inherently hard to tame. For this reason, much of our material progress came from shifting away from biological modes of production. To this day, some products like food remain stubbornly biological and hugely inefficient.

The move away from biological modes of production would leave humans as one of the last biological parts of the economy. Under this framing things like robots, AI, brain emulations, fertility technology, and AI companions can all be understood as ways to displace biological humans in the economy.

I’ll admit, this line of reasoning leaves me feeling a little cold. It’s a classic case of Moloch sacrificing the beautiful and messy for the cold and efficient. I get some comfort from the fact efficient processes have lead to human flourishing; for instance, the Haber-Bosch process provided a non-biological source of fertilizer, roughly doubling the population the world could sustain.

But it’s more heartening to dream about what we might do with all of the resources we would save. Replacing wood and beef would free up more than half the continental United States to become a national park. We could replace wheat with wildflowers, or rewild the great plains with bison, or turn deserts into jungles.

Let’s remove biology from our production processes so there can be more life.

Appendix: places where biology excels

Other places where living things will retain their advantage:

Space manufacture, where you want fully-general systems like yeast to make pharmaceuticals and food. Efficiency is less important than low mass.

Evolving solutions via directed evolution, PRANCE, etc. Though ideally once a solution is found it can be made with modular peptides.

Cell-based medicine e.g. phage therapy, probiotics, gene therapy, growing organs, etc.

Fruits, vegetables, and other plants, like I discussed above.

Though I think there are good opportunities here

And stone, but that’s a different story.

I can’t seem to find this quote anywhere, though I’m sure I read it at one point. Please let me know if you find it.

Even today, dairy can be made significantly more energy efficient using synthetic feed.

Though fertilizer, scientific farming, irrigation systems, grow lighting, and genetic modifications can go a long way towards making them more resource efficient.

Nuts and bolts, I don’t see bioproduction being disfavored since it’s “hard to tame”. We’re getting a lot better at bending it to our will. I think it’s losing ground for reasons of metabolism and chemical environment. Biological systems grow up step by step and each step needs to take place in an environment that’s basically congenial to all the others, so you get complicated pathways that take place in mild conditions, and overall energetics that are the sum of many punishing overpotentials. And of course it can't handle compounds that can't form in water, at neutral pH, at STP, etc.

The energy story explains our long slow transition from biomaterials. The materials of the future have always been made out of energy. From copper to bronze to iron, from iron to Al and Mg, from mud to brick and stone to concrete, wood to engineered wood and plastic, cotton or rubber to nylon or synthetics, the materials future has been getting less about an investment of material and more about an investment of energy. And so biology’s advantages in distributed production and chemical complexity feel less relevant for making the materials the future is made from.

Incidentally, Mahati Chintapalli has a new paper this month on the tradeoffs between chemical and bioproduction in IECR. https://pubs.acs.org/doi/full/10.1021/acs.iecr.4c01958

Word.

When chemistry replaces biology it can feel promethean. Shun the legacy machinery, take our fates into our own hands. Cars so we don’t have to enslave horses to move around. Steel so we don’t need to wait for a forest to grow to build a bridge. Synthetic fertilizer to end our parasitism on bird poop etc.

The new biological technologies like enhanced agronomy or precision fermentation often seem about intensifying and fortifying our dependence on nature. Chemical technologies by contrast seem to be about cutting ties and going our own way.

The bio way fits with a lot of peoples biases about what’s natural and right. But with 10B people on planet earth, humans and livestock now the overwhelming majority of large land biomass, more than half the inhabitable surface of the planet cleared for our use, at some point this picture that we still exist as part of a natural system starts feeling fake. The spectre of Moloch is totally there but going our separate ways starts feeling like the kinder thing to do.